Design Submission

The customer or a graphic designer creates and submits the stamp design, which includes text, logos, and other visuals.

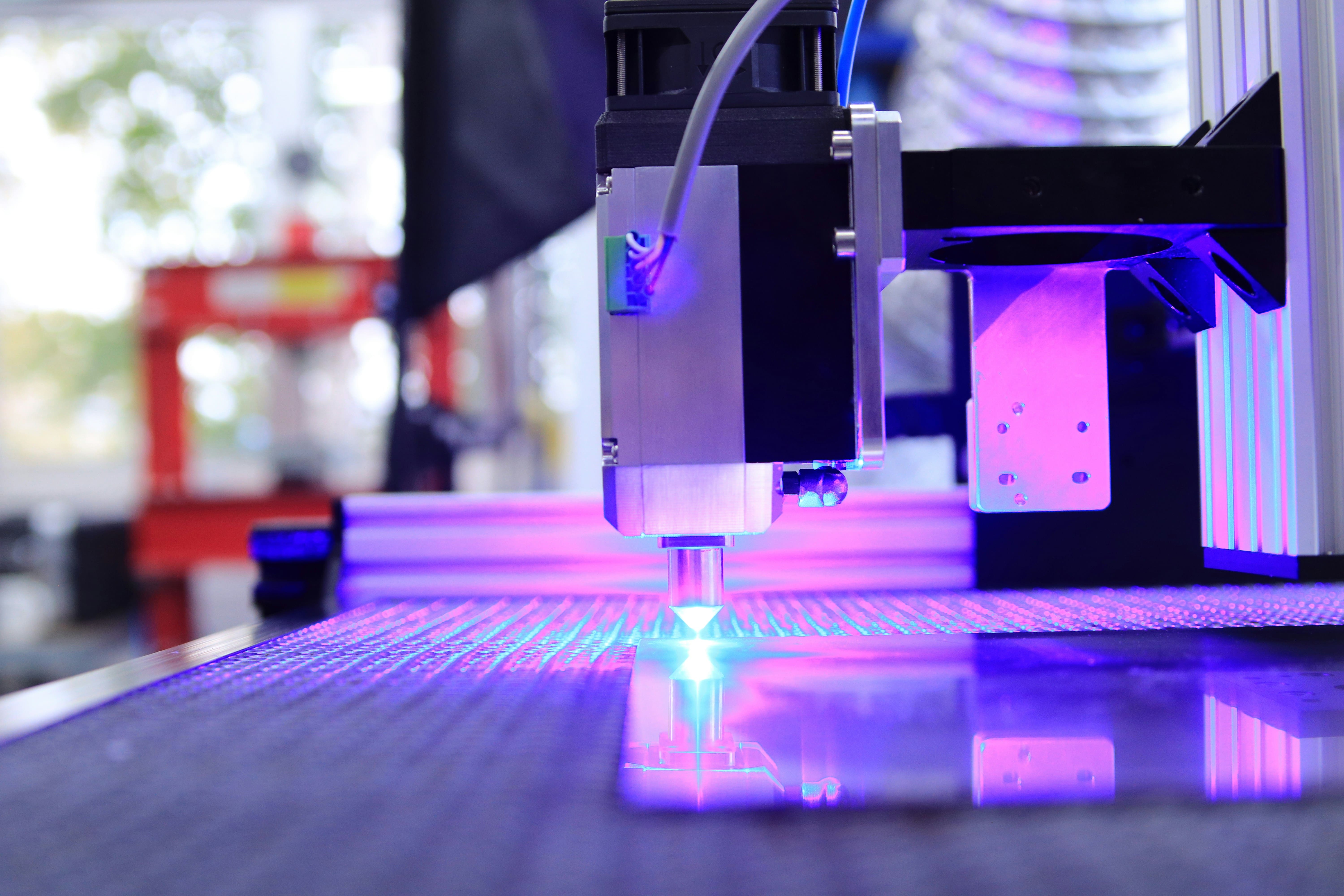

For making stamps, the approach varies significantly depending on whether you are using a professional manufacturing service or crafting them by hand. Professional options include modern laser-engraving and flash machines for high precision, while DIY methods rely on manual carving from materials like rubber or erasers.

For businesses and high-volume orders, a manufacturer like NylonStamp uses a streamlined and precise process.

The customer or a graphic designer creates and submits the stamp design, which includes text, logos, and other visuals.

The design file is converted into a vector format, which allows for perfect scaling without losing image quality.

A computer-controlled laser etches the image directly into a sheet of specialized rubber, removing all negative space.

After engraving, the stamp is cleaned and mounted to its final handle, be it a traditional block or a self-inking mechanism.